In industries like mining, automotive, marine and engineering, well-maintained machine parts are essential to keep operations running smoothly. However, with frequent use, machinery components will eventually become coated in stubborn grease, grime and carbon deposits. If these components aren’t regularly cleaned, you may experience reduced machinery performance or even breakdowns.

As we know, machinery and transport vehicles are made of hundreds, if not thousands of parts and components. The only safe and productive way to clean these parts is with a parts washer. So, can every machine component be cleaned in a parts washer?

Let’s look at what you can and can’t put in a parts washer.

What products are safe for a parts washer?

Parts washers come in a range of sizes. While the temperature, wash cycles and basket speeds are fully adjustable, it’s best to choose a parts washer that suits the items being cleaned.

Small Components

Cleaning multiple small parts like pistons, rods, nuts and bolts usually requires a washer with a lower load capacity and a smaller internal height. These are perfect for cleaning items with minimal carbon build-up.

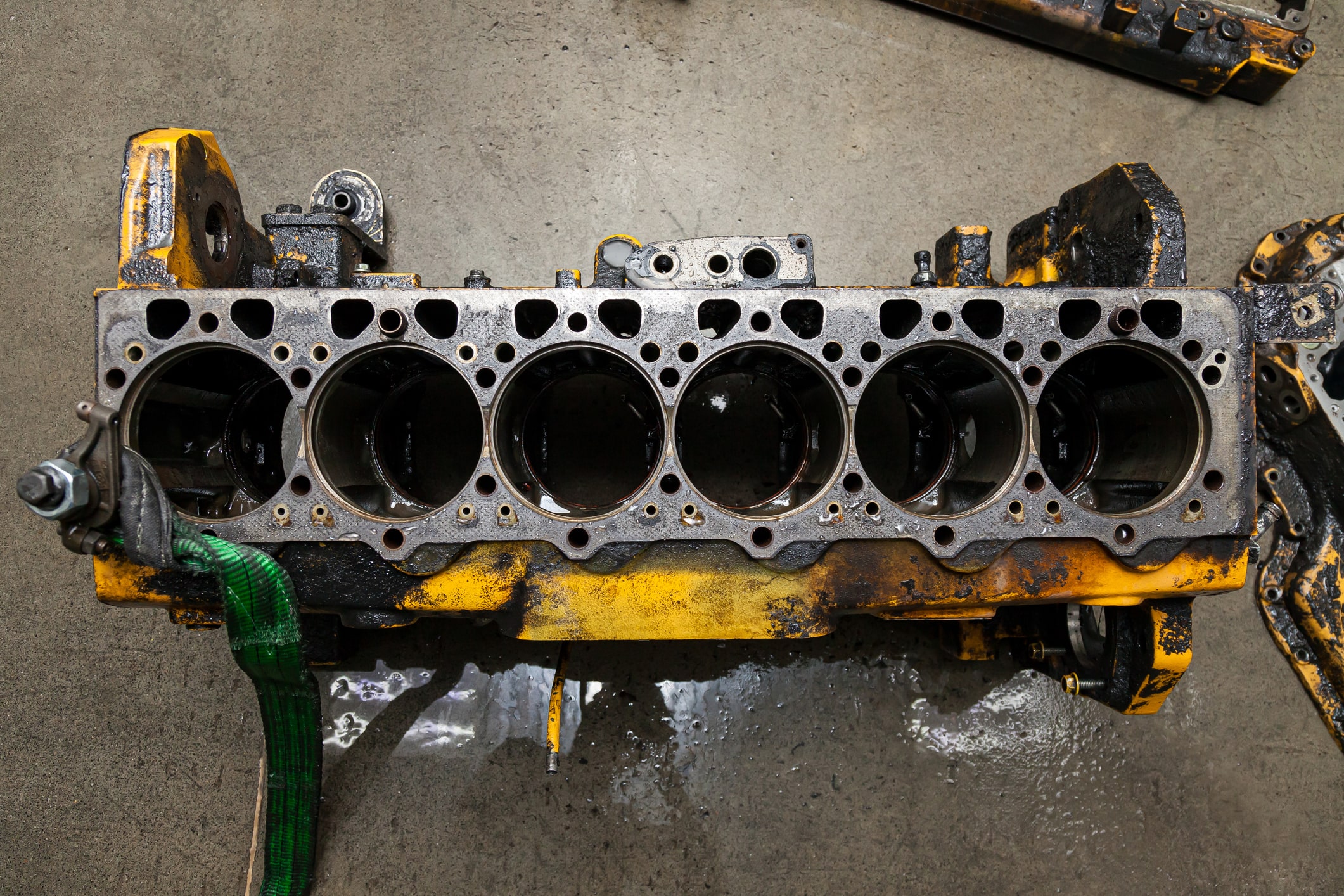

Medium to Heavy Components

For bigger items such as V6 and V8 engines, or heavy carbon deposits on engine blocks, you’ll need a parts washer with a greater internal height and wider basket area. A higher load capacity and a larger basket diameter are essential for these tasks.

Extra-Large and Heavy-duty Components

Industrial-sized parts like Caterpillar engines require specialised heavy-duty washers that can handle extremely high load capacities. These machines are specifically engineered to clean the heaviest carbon deposits.

What products are NOT safe for a parts washer?

As versatile as a parts washer is, there are limitations to what can be safely and effectively cleaned. Understanding these limitations will help you maximise the longevity of your machine parts and the parts washer itself.

Non-compatible metals and plastics

Soft Metals

Certain metals like aluminium, copper and brass can experience some discolouration or even corrosion, which compromises the integrity of the component.

Certain Plastics

While some plastics can safely be cleaned in a parts washer, others, such as certain types of polystyrene, may degrade or warp when exposed to cleaning solvents. Always check the material compatibility before washing plastic components.

Electrical and Electronic Components

It might be tempting to think that a quick run in a parts washer could deal with grimy electrical components. However, doing so risks damaging the electrical integrity of these parts, leading to possible system failures or safety hazards.

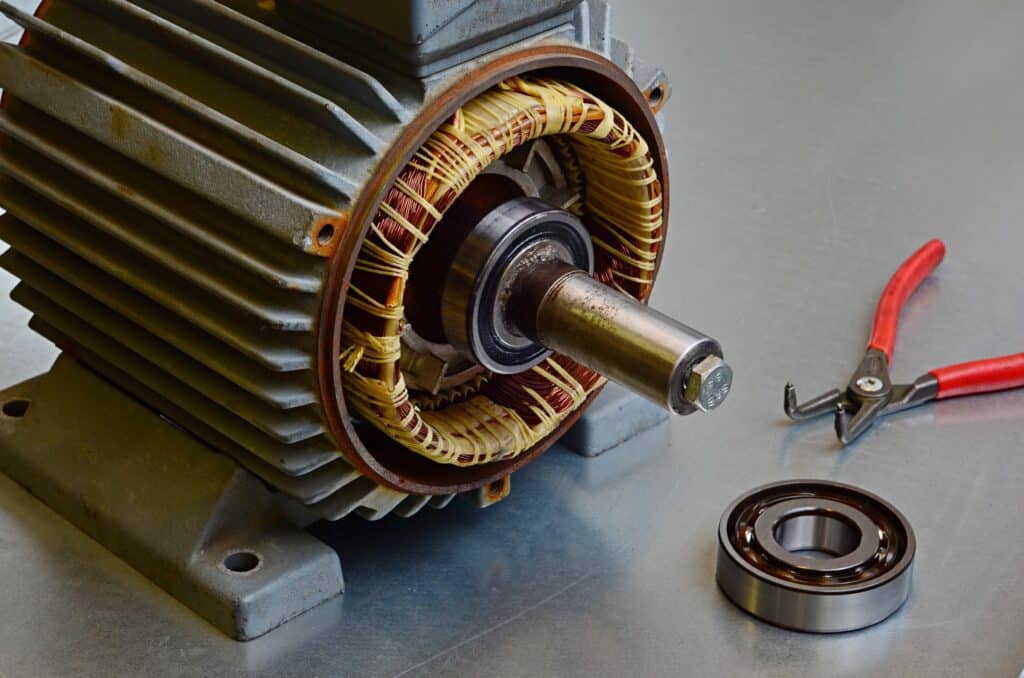

Parts with Sensitive Seals or Bearings

Rubber seals or sensitive bearings can be damaged by the high-pressure cleaning action of parts washers. These are better suited for manual cleaning processes.

Highly Porous Materials

Highly porous materials can trap cleaning solutions, making it difficult to completely rinse them off. This may degrade the material over time.

Complex Assemblies with Hard-to-Reach Areas

While parts washers are incredibly effective at cleaning many types of machine components, they can struggle with complex assemblies where there are areas that the cleaning solution cannot easily reach.

Items Contaminated with Hazardous Materials

Components contaminated with hazardous or toxic substances should not be placed in a standard parts washer. Specialised cleaning procedures are often required for these types of materials to ensure safety and compliance with regulations.

Biological Material

Machine parts that have been contaminated with biological materials should not be cleaned in a parts washer due to the risk of cross-contamination and the potential biological hazards involved.

What cleaning solutions should you use?

The cleaning solution is something that is often overlooked but crucial for effective cleaning. While some industries continue to use harmful and hazardous chemicals, it’s been proven that alkaline-based solutions are better and safer for both workers and the environment.

Robowash’s CF50 detergent is a special formula that is powerful enough to remove grease and grime from both ferrous and non-ferrous metals. It’s also 100% active and highly concentrated, meaning the detergent cleans continuously for the wash cycle. Unfortunately, some water-based chemicals are full of non-active fillers which do nothing to aid the wash process. If you’ve ever ended up with piles of sludge at the bottom or a parts washer, that’s the filler.

For more information on selecting the right parts washer, contact the team at Robowash. With a wide range of parts washers and safe cleaning chemicals, Robowash is Perth’s parts washer specialist.