Anyone who has had the job of removing oil or grease from machinery parts will appreciate the value of an automatic parts washer. Cleaning or degreasing metal and plastic parts by hand can be labour intensive and time consuming. To speed up the process, some will choose to use harsh solvents or hazardous cleaning agents. Unfortunately, many solvents can be both harmful to your health and the environment.

THERE IS A BETTER METHOD.

Aqueous or water-based parts washers are safe and extremely efficient. Apart from using mechanical energy and high-pressure hot water, the only other ingredients are an alkaline salt-based detergent and an anti-foaming agent. Be aware though, not all detergents are the same. Some cheaper detergents will include ‘fillers’ that add nothing to the cleaning process while others will include harmful chemicals.

Let’s take a deeper look at the chemicals used for cleaning machinery parts and find out just how safe they are for you and the environment.

Safe chemicals used in a water-based parts washer

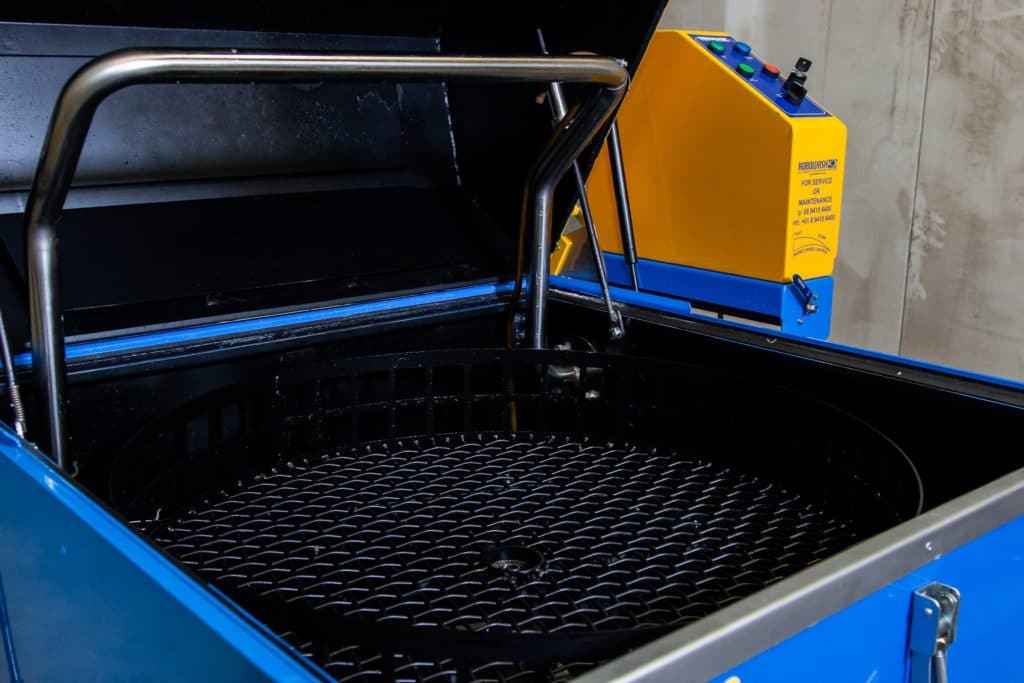

Water-based parts washers, like those manufactured by Robowash, are highly effective at cleaning machine parts using a mixture of water and safe chemical detergents. The chemical detergent (Robowash CF50) can be used on all ferrous and non-ferrous metals and plastics.

The CF50 detergent contains chemicals that are 100% active and highly concentrated. This means that the detergent is not diluted in any way. Unfortunately, there are some other products on the market that include non-active/low-cost ingredients that essentially become ‘fillers’. These fillers do exactly as their name suggests – they add volume to the container or drum but offer nothing to the cleaning process. Even worse, these fillers end up as sludge at the bottom of the parts cleaner adding additional waste to be disposed of.

The other benefit when using the CF50 detergent is an in-built rust inhibitor. This addition ensures that your machinery parts avoid any corrosion or short-term rust forming.

Chemicals to avoid in a parts washer

Solvent-based parts washers were commonplace in trade and industrial warehouses from the 1960s to the 1990s. However, due to the toxic nature of cleaning solvents, most businesses have moved to a water-based parts washing system.

There are some cases, like cleaning internal engine components or rail brake cylinders, where solvents are used to remove heavy grease. It’s still recommended to use a water-based parts washer as the final step to clean any solvent residue from the components.

As well as being hazardous to the environment, harsh cleaning solvents can cause serious health issues for those who come into contact with the chemicals or their vapour. Some common issues include:

- Eye and throat irritation

- Nerve damage

- Skin problems

- Reproductive damage

- Respiratory impairment

- Some types of cancers

The following chemical solvents are still used in some industries and most, if not all, can cause long-term damage if not handled correctly.

Toluene

Toluene is a common ingredient in paints and lacquers but is also used as a cleaning agent for equipment and tools. Exposure to Toluene can cause dizziness, redness and swelling. Long-term use can cause much more serious issues including dermatitis, hearing loss and nerve damage.

Trichloroethylene

This is often used as a degreasing solution but has been proven in studies to be highly toxic and damaging to the health of anyone exposed to it. The vapour can cause nausea and headaches while long-term exposure can affect the kidneys and liver, and cause nerve damage.

Acetone

Apart from being a toxic chemical, Acetone is a major fire hazard. Even in a well-ventilated workplace, the vapour from Acetone can travel and sit in small low-lying pockets. Acetone has a low flash point, meaning it can easily ignite without warning.

Caustic Chemicals

As you can guess by the name, caustic-based chemicals essentially burn away grease and grime. Using a chemical that is so corrosive can be extremely dangerous and should the liquid splash on the skin or in the eyes it can cause severe burns or blindness.

Why water-based parts washers are a better choice

Buying or hiring a water-based parts washer makes perfect sense. We’ve seen how dangerous chemical solvents can be to people’s health and the environment – it’s scary to think that businesses are still using these methods.

The other benefit of a Robowash water-based parts washer is its design. Being fully enclosed means there is no risk of anyone coming into contact with the hot water or detergent. The operator simply pushes the button, and the parts washer does the rest.

If you want to discover even more benefits of water-based parts washers, talk to the team at Robowash. We manufacture, sell and hire parts washers to suit industries of all sizes. Take a look at the full range of parts washers online or contact Robowash today.