The benefits of using a water-based parts washer have been well documented. Both the economic and environmental gains are more than enough to prompt businesses to discard solvent-based cleaning methods and move to an aqueous solution. But the question remains. How effective is a water-based parts washer?

It’s all well and good to introduce an eco-friendly parts cleaning system but is it going to effectively clean the greasiest parts at a greater speed than your current cleaning method? Let’s look at how a water-based parts washer works and see how well it stacks up against the more hazardous hydro-carbon solvent cleaning system.

How a water-based parts washer works

It may seem hard to believe that water alone can clean a grease and grime covered engine block. In a way that’s correct. Though, instead of using harsh solvents, the water-based parts washer uses a mixture of water and a special alkaline salt-based cleaning agent.

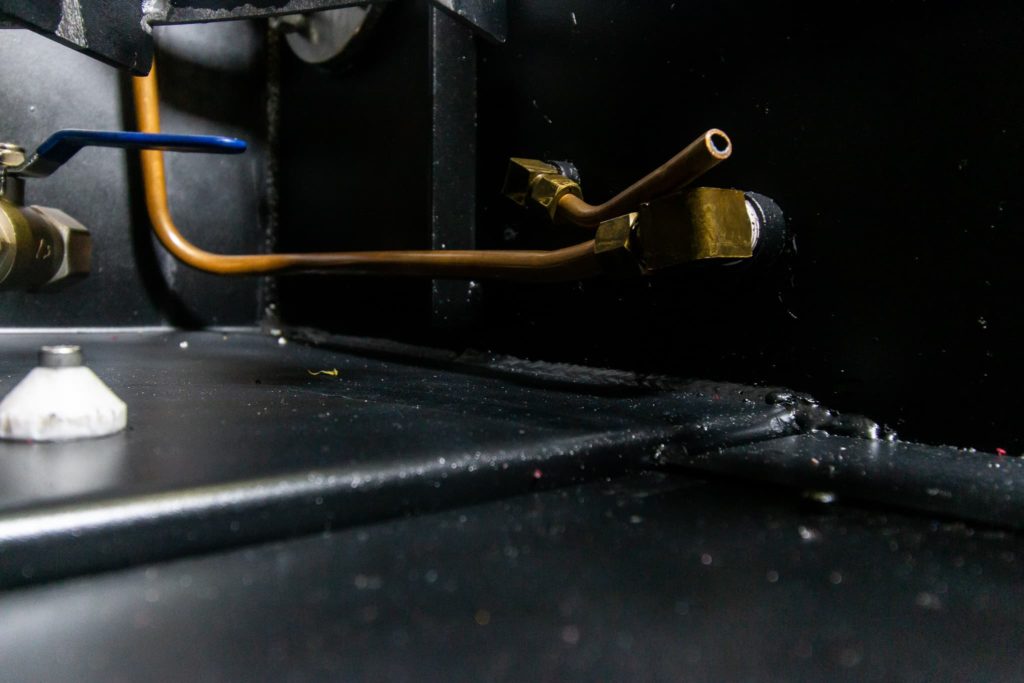

A water-based parts washer

Water-based part washers come in a range of sizes and work in a similar fashion to a large dishwasher – using water, heat, detergent and mechanical energy to clean the parts. There are automatic washers designed to handle smaller precise cleaning for tools or small engine parts. On the other hand, if you need to clean the engine block of a 400-tonne dump truck, you can find a washer to suit that too.

After the part is placed inside the parts washer, the lid is locked and secured in place. The fully enclosed and automated unit ensures your workers are always safe. The combination of motion, heat, high water pressure and a unique non-toxic cleaning agent ensures every part comes out free of grease and carbon build-up.

Alkaline salt-based detergent

The specially formulated detergent used by Robowash is 100% active and highly concentrated. The high-grade ingredients are there to clean, not just add volume (as is the case with some cleaning agents). Using a high-quality detergent means you can run the parts washer for longer.

If you use a non-active, low-cost detergent, this will create a large build-up of sludge in the bottom of your parts washer. This means the machine will need to be cleaned more often and the extra waste disposed of more frequently.

The cleaning agent that Robowash uses is blended with defoamers to prevent the water from foaming during cleaning. It’s safe to be used on both ferrous and non-ferrous metals and plastics and has inbuilt rust inhibitors.

Water-based Vs solvent-based parts washers

Businesses are continually looking for ways to become more eco-friendly and reduce their carbon footprint. While a water-based parts washer is the clear winner for the environment, it needs to prove it can clean as quickly and effectively as a solvent-based parts washer.

Solvents used in parts washers are typically petroleum based, so naturally, they can be highly flammable. The solvents clean by dissolving the dirt whereas a water-based washer uses heat and pressure to break down and remove dirt. As mentioned, the hazardous nature of solvents can be harmful to the environment as well as workers’ health and safety. That alone is enough reason to invest in a water-based cleaning system. The added benefit is, it will clean as good or better than its solvent-based counterpart.

Water-based parts washer Solvent-based parts washer

✔️ Effectively cleans metals ✔️ Effectively cleans metals

✔️ Effectively cleans plastics ✔️ Effectively cleans plastics

✔️ Environmentally responsible ❌Environmentally responsible

✔️ Safe around workers ❌Safe around workers

✔️ Non-flammable ❌Non-flammable

If you want to find out more about the benefits of water-based parts washers, talk to the team at Robowash. We manufacture and distribute parts washers to suit industries of all sizes. Our water-based washers are built strong using 316 stainless steel and can manage parts 3.8m long and weighing up to 6000kg.

Rental and purchase options are available, so contact Robowash today.